Stop Losing Money on Eggs. Seriously.

Farm profit shouldn’t feel like a guessing game. i mean, at first I thought it’d be easy. lol. nope. I mean—it looked easy but turns out… not so much. Disease, poor feed, birds just stop laying. It’s rough, and we’ve been there.

- Trusted By 1000+ Clients

- Commitment to High Standards

- Strategic Poultry Farming Company

Fact

Success in Poultry Isn’t Luck—It’s System

The difference between a struggling poultry farm and a successful one—the kind that hits 280-320 eggs per bird per year—is a system.

Our Pillars

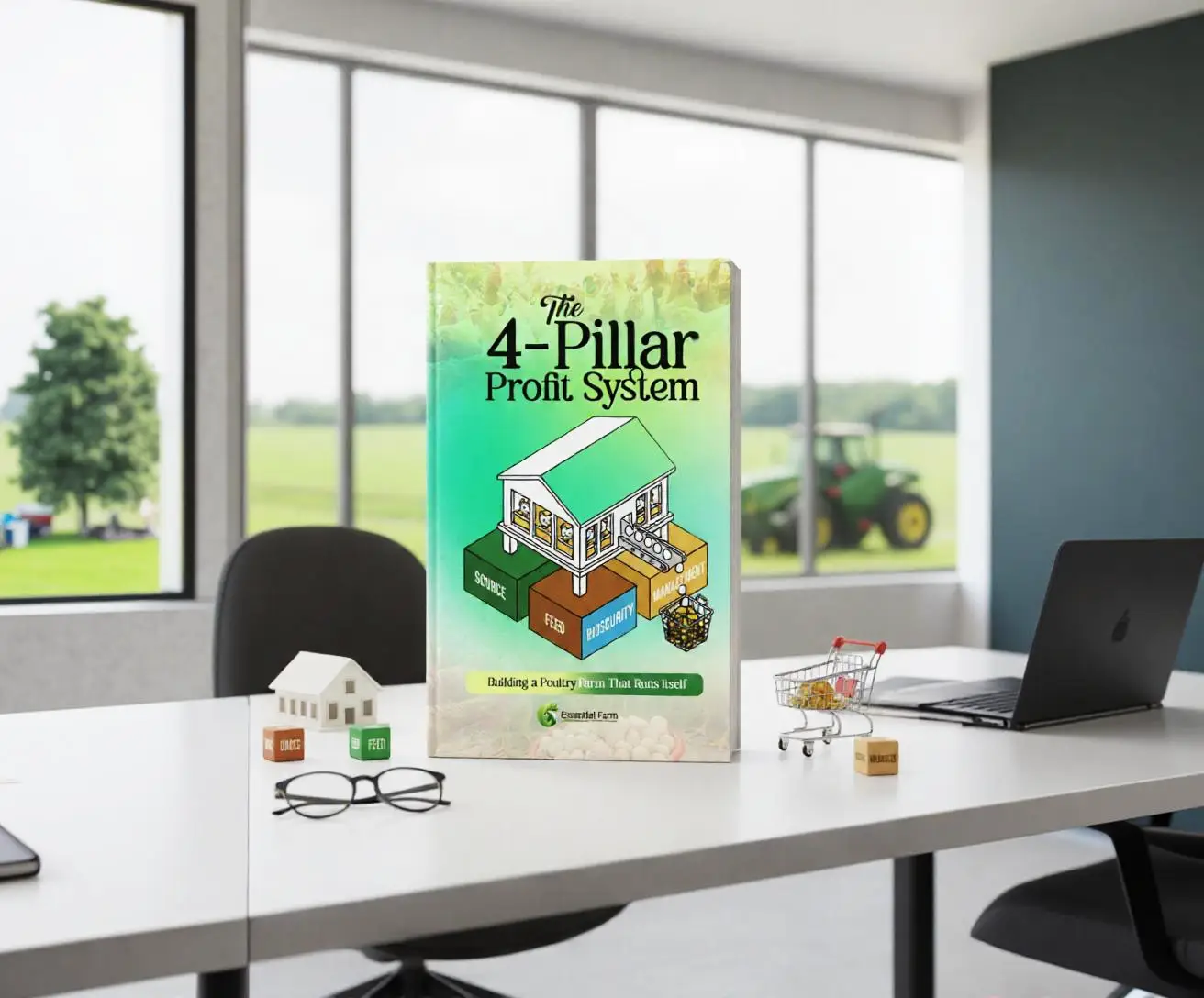

The Essential Farm 4-Pillar System: No Exceptions.

This isn’t some dumb idea or fluffy marketing strategy; it’s the operational framework that lets us run our 2500-bird capacity farm efficiently in Onitsha. If you fail in even one of tehse four areas, your whole business is toast, yes I know that sounds dramatic—whatever.

Everything we do is built on these non-negotiables:

Farm Management (Operational Excellence)

The systems over the chaos. This means proper record-keeping, efficient waste management (that turns droppings into income!), and structured routines for staff. A farm without a system is just a place where you’re raising feed bills.

Biosecurity (Disease Prevention)

This is the protocol that keeps the lights on. Strict control of access, continuous sanitation, foot dips, keeping wild birds and rodents out. We run an All-In, All-Out System to allow for complete house disinfection between cycles. It’s the non-negotiable protocol.

Type of Feed Given (Nutrition)

Nutrition is the backbone of egg quality and production. High-calcium Layer Mash for strong shells, precise Grower Mash at the right time. Cutting corners here sucks, and you’ll see the cost in breakage losses and low yield.

Source of the Birds (Genetics)

We don’t beleive in cheap deals. Your laying capacity is set the day you buy the chick. We source only high-quality Day-Old Chicks (DOCs) from reputable hatcheries because poor genetics mean reduced output and weak shells. If the source isn’t right, you’re already sunk.

Our Core Services:

The Farm Operations We Mastered

We’re an egg production farm, but we also offer services based on the exact, proven processes that make us profitable. We literally sell the byproducts of our own success

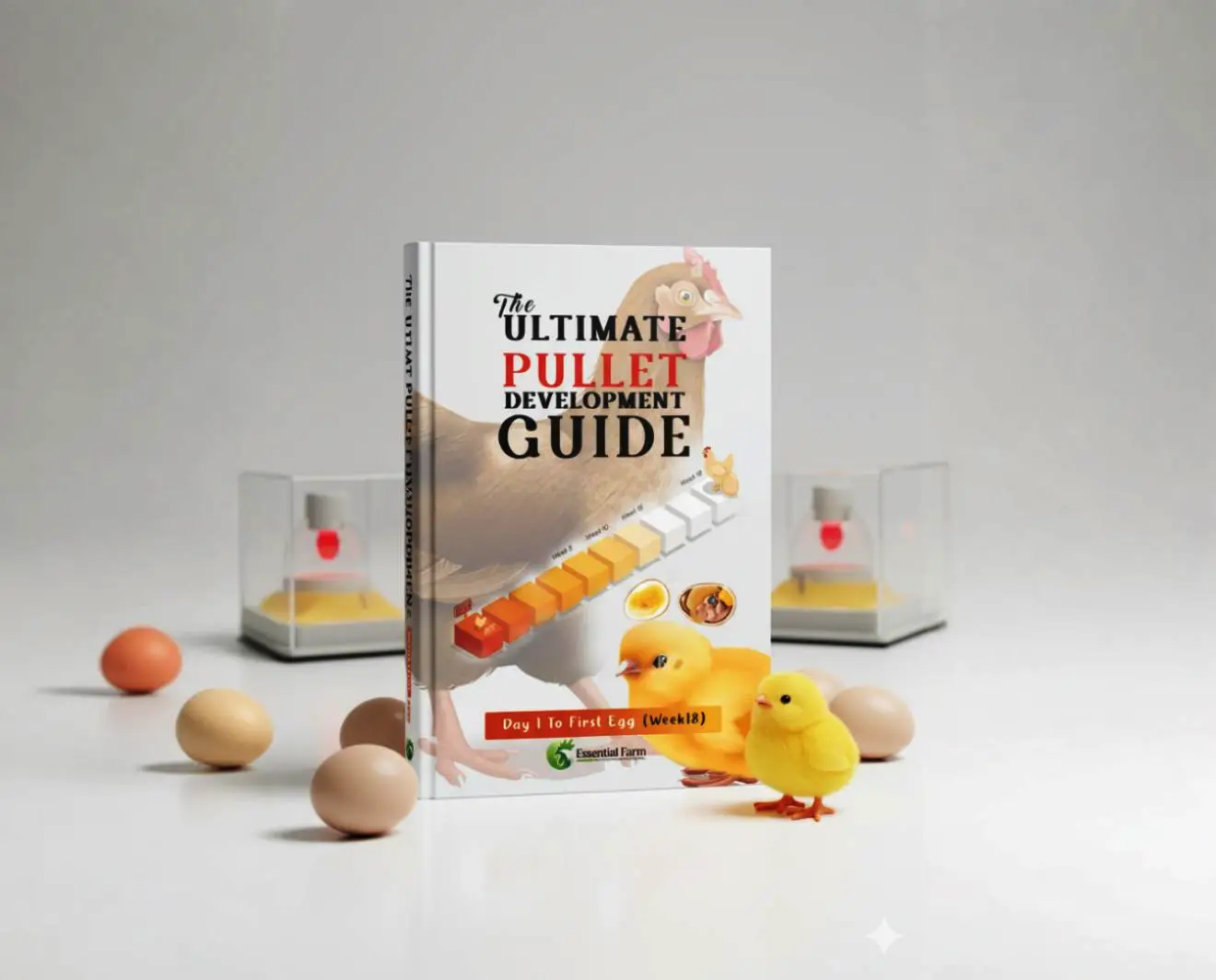

(Day-Old Chicks to Week 18)

This is the most crucial part, no, really. You can toast your entire investment in the first month if you mess up brooding. We raise both layers and broilers for ourselves and clients, focusing on building strong, resilient birds ready for peak production.

Initial Setup

Receiving the DOCs, we immediately administer glucose and anti-stress supplements. We keep temperatures high (around 35^{\circ}C initially).

Deep Litter Phase (Weeks 1-13)

The birds live on a deep litter system where they can move around and socialize. This phase focuses on skeletal development and critical vaccinations.

The Critical Week 13 Transfer

This is non-negotiable. We move the birds from the floor-based deep litter into the Battery Cagesaround Week 13. Why? It gives them 5-7 weeks to adjust and reduce stress before their first egg drops (Week 18). Stress equals low output.

Anti-Coccidial Treatment:

We administer this essential medication early, typically during Days 9-12, to prevent Coccidiosis, which is an intestinal killer for young chicks.

(Layers for High Yield)

Our entire farm is designed for high-volume, high-quality egg output. We use the Battery Cage System to maximize space, ensure hygiene, and simplify egg collection. Our goal is always to keep the flock laying in that sweet spot of 280-320 eggs per bird per year.

Quality Control

We don’t just collect eggs; we focus on shell strength, which is directly tied to our Type of Feed Given We ensure the correct high-calcium Layer Mash is used.

Farm Management

Our workers follow strict protocols for daily egg collection, feed refill, and environmental checks to prevent breakage and ensure clean handling

Vaccination, Deworming, and Supplementation

We are strictly preventative. Waiting until disease hits is financial suicide. Our health strategy is detailed and consistent:

Vaccinations (Broilers or Layers)

We follow a set schedule for vaccines like ND and Gumboro. Crucially,we give a 24-hour window of Multivitamins and Electrolytes before and after every shot. This reduces the stress and maximizes the bird’s immune response to the vaccine.

Deworming Schedule

This is often skipped, and it’s a huge mistake. We deworm at Weeks 9 and 14, and then repeat it every 6-8 weeks during the laying cycle. Parasites eat your profit, period.

Antibiotics

We never use antibiotics haphazardly. It’s only for therapeutic use when prescribed by a qualified vet.

Debeaking & Selling Old Layers

These are hard, necessary management tasks tied directly to your profit margins.

Debeaking

Done around Week 8-10 during the growing phase. It’s not optional for cage systems. We do it to prevent aggressive pecking (cannibalism, yes I know that sounds dramatic—whatever) and to reduce expensive feed waste. It’s about maintaining flock order.

Selling of Old Layers

When the lay rate drops below profitability, we execute the cull. This isn’t just selling old birds; it’s the final, critical step in the All-In, All-Out System. It allows us to completely empty the house for a full, proper disinfection, breaking the cycle of accumulated disease vectors. No free riders here.

Advantages

Why Choose Essential Farm? We Don't Guess. We Document.

You shouldn’t trust your money to a farm that uses “feelings” or “old methods.” We don’t. We use a documented, profitable system that works here in Africa

We Teach Our Pillars

Unlike other farms, we don’t just sell eggs; we sell the knowledge behind the eggs (the 4-Pillar System). You get transparency on our feed quality, biosecurity measures, and sourcing.

Process, Not Promise

We give you the exact weekly timelines (Week 13 transfer, Week 8-10 debeaking, 6-8 week deworming). You know exactly what we are doing and why.

Biosecurity is Life

Our commitment to the All-In, All-Out System, dedicated personnel hygiene, and continuous pest control is the only reason we stay profitable. We mitigate risk so your investment is safer.

Zero-Waste Profit Strategy

We run a system where nothing is just “waste.” We see droppings as income (organic manure), and older birds as the final step in the All-In, All-Out hygiene cycle. We teach you how to squeeze maximum value from every single input, turning liabilities into cash. (Links to Pillar 4: Farm Management).

Genetics Guarantee

We don’t just sell Day-Old Chicks (DOCs); we sell Pullet Development that is 100% ready for the cage. Our Critical Week 13 Transfer process eliminates adjustment stress, ensuring your birds hit the ground running at Week 18. Your laying bird is a precision instrument, not a gamble. (Links to Pillar 1: Genetics and Service 1: Brooding).

Quality Shells, Fewer Losses

Our focus on Type of Feed Given (Pillar 2: Nutrition) isn’t academic—it’s about your bottom line. Strong eggshells mean fewer breakage losses during collection and transport. We document the feed specification that keeps our losses under $2%$ (or your documented low figure) and pass that exact specification on to you.

FAQ

Frequently Asked Questions

Why is Biosecurity so strict?

Because waiting for disease to hit is financial suicide. Biosecurity is the non-negotiable operational protocol that keeps the lights on. It’s about strict control of access, continuous sanitation, and keeping wild birds out. We run the All-In, All-Out system to break the disease cycle entirely.

What is the Critical Week 13 Transfer?

It’s the most high-risk, high-reward move you will ever make. It’s when we move the birds from the floor-based grow house to the new Battery Cages. We do it at Week 13 (early!) to give the birds 5-7 weeks to fully adjust to the cages and the nipple water system before they start laying at Week 18. Stress equals low output.

Why are my eggshells suddenly weak and breaking?

90% of all weak shell problems is a dumb idea caused by your Type of Feed Given. You are either cutting corners on the high-calcium Layer Mash spec, or your bird is not absorbing it properly due to gut parasites. You have to be aggressive with calcium loading in the final 4 weeks before lay.

Why do you deworm so often? I usually skip it.

That’s a huge mistake. Parasites are eating 10 to 20% of your profit, period. The worms consume the nutrients meant for the egg. We deworm at Weeks 9 and 14, and then repeat it every 6-8 weeks during the laying cycle. If you don’t deworm, you’re just feeding parasites.

When do you use Antibiotics?

Never haphazardly. We are strictly preventative. We only use Antibiotics for therapeutic use when a disease is confirmed and prescribed by a qualified vet. Overusing them is expensive and builds resistance. Our core focus is prevention (vaccination/supplements), not cure.

What is the 80% Uniformity Rule?

This is the single most important predictor of profitability. It means 80% of your flock should be within ±10% of the target weight at any given check. If your uniformity is low, you have some birds laying tiny eggs and others not laying at all, causing chaos in management and destroying your profit margin.

Should I debeak my birds?

For cage systems, yes. We do it around Week 8-10 during the growing phase. It’s necessary to prevent aggressive pecking (cannibalism, yes I know that sounds dramatic—whatever) and to reduce expensive feed waste from flicking feed out of the trough. It’s about maintaining flock order and profit.

What is the All-In, All-Out System?

It’s the only way to manage biosecurity long-term. It means you clear 100% of the birds from a house before bringing in the next batch. This allows for a full, proper house disinfection (a 100% disease break). It stops the accumulation of disease vectors that wipe out continuous-flow farms.

Every single action we take—from ordering a truckload of feed to opening a cage door—is governed by these four pillars.

Who we are

Systems Over Chaos

We are an egg production farm that sells the exact, proven systems we used to stop hemorrhaging cash here in Onitsha. We literally sell the byproducts of our own success. We don’t guess. We document.

The 4-Pillar Non-Negotiable

Everything is built on 4 absolutes: Genetics, Nutrition, Biosecurity, and Operational Excellence. If you fail in even one, your whole business is toast.

The 18-Week Pullet Guarantee

Our core service. We specialize in building the bird right from Day 1, focusing on the non-negotiable Critical Week 13 Transfer to eliminate adjustment stress and guarantee an 18-week Point-of-Lay.

Biosecurity is Life

We run a strict All-In, All-Out System to allow for complete disinfection between cycles. The 48-hour multivitamin/electrolyte protocol before and after every shot is mandatory. We mitigate risk so your investment is safer.

Zero-Waste Profit Strategy

We see droppings as income (organic manure) and old birds as the final step in the hygiene cycle. We teach you how to squeeze maximum value from every single input.

We Sell the Knowledge

We don’t just sell eggs or services; we sell the documented, transparent process behind the eggs. You get the exact weekly timelines, protocols, and feed specifications we use ourselves.

Each blueprint is Made with Love

Grow with us today

Stop losing birds and start counting profit.

Explore Our Ultimate Pullet Development E-Book Now

And More

Blog

We Know a Lot About The Essential farm

Free Quote & Consultation

We’re here to help with all your urban landscape design needs.

- Complete Garden Makeovers

- Professional Landscaping

- Premium Turf Installation

- Garden Design & Planting